Navigating RFID Implementation – How to Overcome Three Common Challenges

Did you know that many industries, including retail, healthcare, logistics, and manufacturing, are increasingly adopting RFID technology? The driving force behind this is their desire to streamline operations with automated data collection and real-time visibility.

The true potential of RFID lies in its ability to digitally identify assets and products in bulk and without line of sight - all in real-time. However, when implementing RFID, the lack of synergy between printers, RFID labels, and legacy systems can lead to performance issues and undermine the operational effectiveness of RFID. Below, we explore three common challenges you may encounter when adopting RFID and demonstrate how our printer technology can help you overcome them.

Challenge 1 – Diverse Labels and Applications

RFID labels are not a one-size-fits-all solution. For instance, hospitals commonly tag most high-value medical equipment with special “on-metal” labels as metal casings interfere with RFID signals. Therefore, solution providers and system integrators must accommodate different label constructions for varying applications. Unfortunately, the solution isn’t as simple as utilizing different printer models to accommodate different label types. Similarly, IT teams desire printers that work with their existing label types and accommodate new label constructions introduced in the future. This ultimately will allow them to minimize downtime and costs relating to new printer acquisitions and maintenance.

Tip: Deploy printers that support a wide range of label constructions and can continuously validate and accommodate new ones to keep pace with evolving demands. Choose printers that adhere to industry standards to meet diverse application needs.

Challenge 2 – High-Speed Production and Error Prevention

Every second counts in a fast-paced industrial setting—such as production lines or logistics facilities. Printing delays and encoding errors can cause major bottlenecks and inflate operational costs significantly. Case in point, manual intervention for reprints slows down throughput and increases the likelihood of human error, leading to inaccurate data and tracking issues.

Tip: Take advantage of TSC Auto ID’s proprietary Encode During Print functionality to reduce overall printing times and boost efficiency. Moreover, RFID printers must ensure that only accurately encoded labels enter circulation. TSC Auto ID’s encoding validation algorithms eliminate the need for manual verification, streamlining your operations and minimizing errors.

Challenge 3 –Integration Barriers

Organizations require devices that deliver high performance yet can be integrated seamlessly with their legacy systems. Unfortunately, due to the lack of in-house technical expertise and reliance on systems integrators, integration can become complex and protracted with less-than-ideal results.

Tip: Deploy devices that integrate quickly into existing workflows and systems, streamlining management and boosting operational efficiency.

The chart below illustrates how two of our printers with newly added RFID functionality can help you overcome these challenges:

| Key Challenges | MB241 Series Industrial Label Printer | TH Series 4-Inch Desktop Label Printer |

|---|---|---|

| Diverse Labels and Applications | Versatile Media Support: Handles a wide array of RFID labels, including on-metal labels up to 1.65 mm thick. | Broad Media Support Supports standard RFID labels and select on-metal labels. |

| ||

| High-Speed Production and Error Prevention |

| |

| Integration Barriers | Free UniPRT SDK: Simplifies new printer integration with existing systems and supports large-scale deployments. | |

Which to choose?

|

|

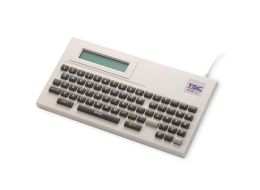

| Ideal for higher-volume operations and applications requiring specialized label types. | Ideal for lower-volume, diverse label printing. |

Please contact your local TSC Auto ID representative to learn more , or visit our website to explore other RFID printers.