Welcome to Our Blog

Get the latest information on new products and solutions, trending industry topics, best practices, tip and tricks, and much more.

Automotive

1429

/en/blog/automotive

Barcode Inspection

418

/en/blog/barcode-inspection

Company News

415

/en/taxonomy/term/415

Cybersecurity

1466

/en/blog/cybersecurity

Events and Tradeshows

1421

/en/blog/events-and-tradeshows

Food & Beverage

1426

/en/blog/food-beverage

Healthcare

1425

/en/blog/healthcare

High Resolution

414

/en/blog/high-resolution

Industry Trends

1419

/en/blog/industry-trends

Manufacturing

1424

/en/blog/manufacturing

Mobile Printing

1420

/en/blog/mobile-printing

Partner Perspectives

1465

/en/blog/partner-perspectives

Remote Printer Management

1432

/en/blog/remote-printer-management

Retail

1423

/en/blog/retail

RFID

416

/en/blog/rfid

Software Solutions

1433

/en/blog/software-solutions

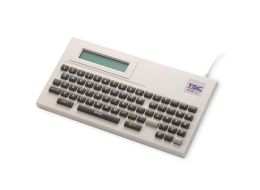

Standalone

419

/en/blog/standalone

Supplies

417

/en/taxonomy/term/417

Tips & Best Practices

1431

/en/blog/tips-best-practices

Transportation & Logistics

1422

/en/blog/transportation-logistics

Warehouse & Fulfillment

1427

/en/blog/warehouse-fulfillment

In modern medicine, blood transfusions are a vital procedure that saves countless lives every day. But the misidentification of patients or blood bags due to human error can turn a life-saving procedure into a fatal mistake. Consequently, many healthcare providers today are seeking to further enhance patient safety by adopting RFID wristbands and blood bag labels. But there are many different types of RFID, so which RFID is best for wristbands and blood bag labels?

Whether as a patient or a visitor, there’s a pretty good chance you've come across the now ubiquitous patient wristband at your last hospital visit. While now a routine part of healthcare operations, receiving hospital care and treatment before wristbands was fraught with human error, with potentially deadly results.

As more industries, from logistics and manufacturing to retail and healthcare, adopt increasingly more enterprise mobile computers (EMC), organizations face growing attack surfaces—not from the devices themselves, but from gaps in security and a lack of lifecycle management. Therefore, it is more important than ever to have a robust digital defense in place.

A robust security posture requires a holistic approach that accounts for the multitude of potential threats and attack surfaces. Crucially, this defense must integrate device lifecycle security to apply processes and tools throughout the entire journey of an EMC—from acquisition and deployment through active management and decommissioning. This is essential because it moves beyond fixing problems after they occur and instead proactively integrates security into every stage.

In our interconnected digital world, businesses of all sizes—from local shops to global logistics firms and retail chains—rely on a vast network of connections to operate. While bringing untold benefits, these connections are also potential entry points for unscrupulous actors to access, breach, or disrupt enterprise systems. Among these entry points is your thermal printer. While serving an important function within business operations, they are often overlooked in cybersecurity planning. Are your thermal printers secure?

In our interconnected, digitalized world, cybersecurity isn't just an IT concern—it's a fundamental necessity. However, navigating through the multitude of security measures available and evolving threats can quickly become overwhelming. The good news is that the People, Process, and Technology (PPT) Framework can help you structure your thermal printer and enterprise mobile computer (EMC) security. That framework is built upon three pillars and is a holistic approach that extends beyond just the technical aspect of cybersecurity.

Since coming into effect on July 25, 2024, EU’s Corporate Sustainability Due Diligence Directive (CSDDD) requires retailers to demonstrate clear and measurable sustainability outcomes. Retailers today face increasing pressures from regulators, investors, and consumers to visibly commit to sustainability. Despite this, many retailers are struggling to translate their ambitions into tangible, credible results across both their stores and distribution centers.

In today’s retail environment, rising customer expectations and the growing complexity of omnichannel operations make accurate inventory management a must-have. Poor inventory accuracy doesn’t just impact operations—it results in lost sales, shrinkage, and a diminished customer experience.

Distribution centers (DCs) are the foundation of modern retail fulfillment. In a landscape defined by speed, precision, and customer expectations, DCs largely shape how quickly and accurately inventory flows across the entire retail network. As fulfillment complexity grows, there is no room for bottlenecks, blind spots, or outdated systems.

In unified commerce, the store has become more than just a point of sale—it's now a fulfillment hub, a service point, and a brand experience center. Store teams play a critical role in retail transformation—but they can only succeed when empowered with timely data and adaptive technologies. Empowering store execution means bridging the gap between business vision and day-to-day execution.

Continuing from our previous discussion on item-level tracking and digital transformation, this article explores how GS1 Digital Link and item-level tracking work together to connect physical products with rich digital data. Adopting these new standards can help retailers stay competitive in today’s retail landscape by unifying operations, improving traceability, and enhancing customer engagement.