Transportation & Logistics

Automotive

1429

/en/blog/automotive

Barcode Inspection

418

/en/blog/barcode-inspection

Company News

415

/en/taxonomy/term/415

Cybersecurity

1466

/en/blog/cybersecurity

Events and Tradeshows

1421

/en/blog/events-and-tradeshows

Food & Beverage

1426

/en/blog/food-beverage

Healthcare

1425

/en/blog/healthcare

High Resolution

414

/en/blog/high-resolution

Industry Trends

1419

/en/blog/industry-trends

Manufacturing

1424

/en/blog/manufacturing

Mobile Printing

1420

/en/blog/mobile-printing

Partner Perspectives

1465

/en/blog/partner-perspectives

Remote Printer Management

1432

/en/blog/remote-printer-management

Retail

1423

/en/blog/retail

RFID

416

/en/blog/rfid

Software Solutions

1433

/en/blog/software-solutions

Standalone

419

/en/blog/standalone

Supplies

417

/en/taxonomy/term/417

Tips & Best Practices

1431

/en/blog/tips-best-practices

Transportation & Logistics

1422

/en/blog/transportation-logistics

Warehouse & Fulfillment

1427

/en/blog/warehouse-fulfillment

With the boom in e-commerce and omnichannel fulfillment, warehouses have become crucial and are growing in number. This growth has led to a surge in warehouse vehicles like forklifts, with the market projected to grow by 40% from 2023 to 2031. These vehicles are vital for moving inventory on the premises. For operations that rely heavily on them, a mobile printer with a shoulder strap isn’t enough. Additional accessories are necessary to streamline the labeling process.

Linerless is emerging as a favored labeling solution. Whether in retail, logistics, healthcare, or beyond, enterprises are seeking a greener, more efficient labeling experience. Dive into our ultimate Q&A guide below to help you make informed decisions on integrating Linerless Labeling into your operations for sustainable and streamlined labeling.

Logistics operations are vital for any business supply chain, enabling product flow from the producer or supplier to the end-users, or vice-versa. Mobile printers are essential in this dynamic setting, compared to stationary printers. Although mobile printers align with the “on-the-go” nature of logistics operations, specific requirements may vary based on the working scenarios or environments. When making decisions, it's crucial to consider elements such as mobility requirements, media usage, durability, charging capabilities, and working conditions.

Warehouse and logistics are the hidden success behind nearly every business operation, ensuring items move through the supply chain at the right place and time. Speed and efficiency are critical in these industries, and labeling is no exception. Labeling is essential in item, box, and pallet tracking. The key is performing this action quickly and efficiently. Adopting linerless applications can benefit warehouse and logistics businesses in three important ways: improved operational efficiency, reduced costs, and a safer and more sustainable business.

Businesses today actively seek ways to minimize their environmental impact and enhance workplace safety. One effective approach is transitioning from traditional labels to linerless labels. This transition not only reduces environmental impact but also aligns seamlessly with regulatory compliance, significantly enhancing operational efficiency.

Sustainability has emerged as a pivotal factor across numerous industries, driven by environmental protection and shifting consumer tastes. Businesses are progressively directing their attention towards sustainable strategies, encompassing endeavors like minimizing carbon footprints, embracing eco-conscious materials, and integrating circular economy concepts. Sustainability arises significantly in the Automatic Identification and Data Capture (AIDC) industry, leading to a growing demand for more eco-friendly materials and solutions for labels, tags, and other AIDC offerings. Reducing carbon emissions is the key strategy for the AIDC industry to achieve carbon neutrality and support environmental sustainability.

VDC Research finds that increasing demand for industrial printers is propelled by automation in manufacturing, traceability regulations in the food and beverage sector, hybrid retail strategies, e-commerce-driven logistics growth, and a heightened safety emphasis in healthcare.

In today's world, there is a great variety of media available to meet the growing demands of diverse printing applications. While having the ability to print long labels and specific labels for various vertical market applications is important, achieving precise printing is a different challenge altogether. These labels often pose difficulties as printers are typically designed for common or frequently used media. Additionally, printers need to be able to adjust for special or difficult media. That's where the TH DH Series comes in, offering an easy solution for printing difficult labels. The TH DH Series is specially designed to provide end users with precise label printing capabilities, with vertical DPI (dots per inch) being a key factor in achieving this level of accuracy.

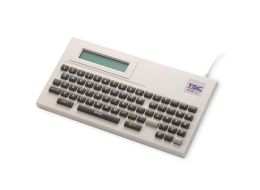

Printer management is necessary for the proper functioning and completion of print jobs. Tasks such as printer configurations, condition monitoring, and troubleshooting are essential. However, managing printers, especially on a large shop floor or printer fleet, can be challenging. That’s why real-time remote management is a vital aspect of printer management as it allows for printer control from anywhere on the premises. The TH DH Series Desktop Printer enhances real-time remote printer management in three ways: the Internal Embedded Webpage, the virtual control panel, and two software tools-TSC Console and SOTI Connect.

When you purchase apparel items, you will notice they always come with a hang tag and a care label. Based on Federal Trade Commission (FTC) and European Union (EU) regulations, labels are required on apparel products to clearly state necessary information in order to sell to end consumers. Typically manufacturers have the labels printed by service bureaus specializing in these types of labels. However, this approach has limited flexibility for change since the label contents have already been set. It also results in additional costs to print new labels and makes it harder to manage inventory for the variety of labels. Manufacturers can use an in-house label printer to overcome difficulties and conquer apparel label printing with ease.