端到端全面部署:RFID追蹤溯源解決方案

現今,各大企業廣泛運用RFID技術追蹤資產和管理庫存,然而不同產業在實際應用上,面臨的挑戰也不盡相同。例如在電子製造業中,抗靜電 (ESD) 包裝材質與電路板上的金屬元件等環境因素,都可能干擾RFID訊號的傳遞,當大量庫存堆疊,更會顯著降低辨識度。同樣的,在文件追蹤應用中,文件若層層堆疊,也可能因為訊號被遮蔽,而導致單一文件難以被辨識。

作為RFID全方位解決方案的供應商,Inchz IoT可依據客戶的具體需求,量身打造全面的RFID解決方案,協助客戶精準解決疑難雜症。憑藉在營運與流程方面具備豐富專業知識,Inchz IoT能夠重新規劃與優化工作流程,從根本解決問題。其解決方案已廣泛應用於製造業、零售業和政府單位。Inchz IoT的RFID解決方案與TSC Auto ID桌上型和工業型RFID印表機無縫整合,為客戶提供最完整全面的支援。

解決方案概述

INCHZ IoT提供一套全方位的「追蹤溯源平台」,可進行雲端資產追蹤與庫存管理。此解決方案整合了硬體、軟體與既有系統,確保各個作業環節緊密銜接。

在硬體方面,Inchz IoT提供RFID印表機與耗材,並支援標準與RFID抗金屬標籤。解決方案也遵循GS1標準,採用GS1 RFID編碼方式。RFID讀碼器可安裝於倉庫、辦公室、門口、大門與走廊等關鍵位置,以利追蹤和識別資產,此外,追蹤資產的所在位置與方向的解決方案亦含納其中。

軟體則包括標籤列印與編碼工具,供使用者根據需求準確編碼列印RFID標籤。此外,透過懸掛式讀碼器,可以有效監控資產,亦針對特定場景進行客製化應用。此平台能與 SAP、Oracle和Microsoft等主流ERP和WMS系統完美整合,可即時追蹤每一件物品。

藉由整合軟硬體,此解決方案可利用RFID閘門自動化進出貨流程,簡化作業並提升整體效率。

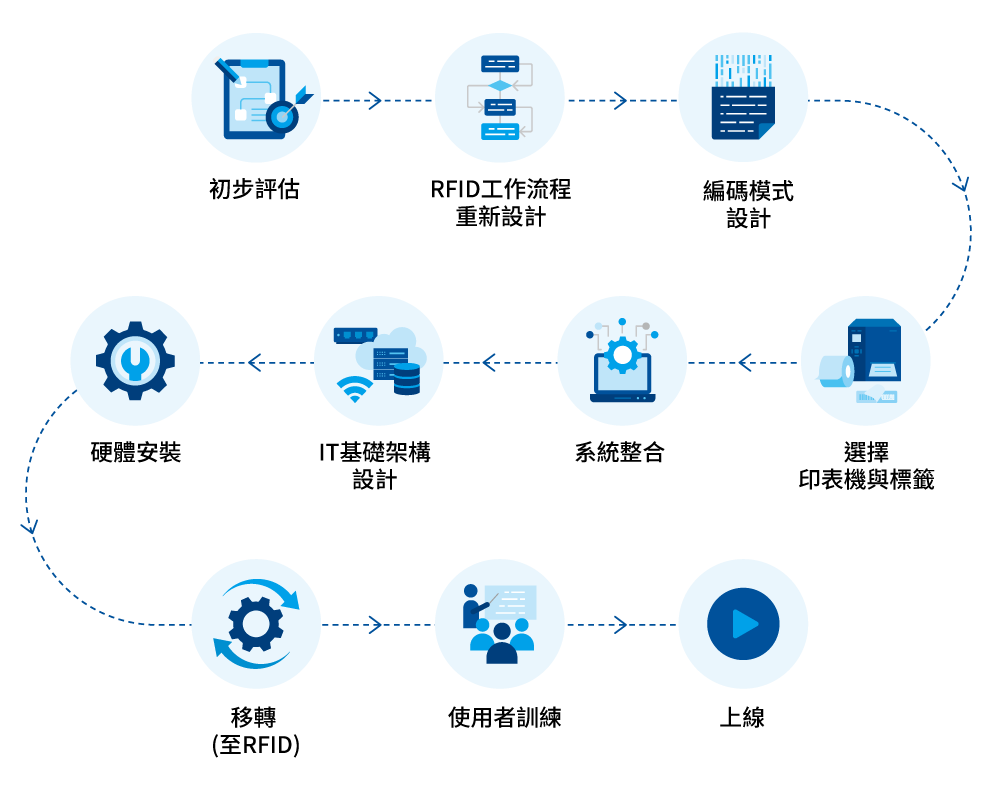

Inchz IoT的導入流程涵蓋三大階段,確保客戶能順利部署並發揮最大效益:

瞭解客戶需求

首先進行現場評估,了解現有工作流程並設定目標,並著手準備,如重新設計工作流程和標籤編碼邏輯,確保符合標準化的識別架構。

設計解決方案

依據客戶需求,選擇適合的硬體設備與標籤類型、進行系統整合測試以確保相容性、同時評估和優化客戶的IT架構,包括交換器、Wi-Fi、伺服器主機和雲端環境等基礎設施。

部署解決方案

開始安裝與調整硬體設備,協助客戶從傳統條碼標籤移轉至RFID標籤。此外也提供使用者訓練、上線支援和變更管理,協助客戶順利轉型。

使用者優勢

此全方位解決方案為客戶量身打造,根據實際營運需求調整設計,能與既有管理系統無縫整合。透過完善與高度整合的RFID系統,可為企業實現多項效益:

- 降低錯誤風險:防止未經授權的操作中斷流程,同時減少人為疏失,例如出貨錯誤或SKU配對錯誤,避免重工的情況。

- 提升庫存準確度:RFID技術能提升庫存資料的可靠性,強化企業對數據的信任。追蹤解決方案還能提高運輸途中的產品與回收容器等物品的可視性。

- 促進生產力:透過減少錯誤、提升資料準確度,同時也降低人力需求、解決人力短缺問題,藉此大幅改善營運效率。

為什麼要選擇TSC Auto ID

選擇適合的RFID印表機,對於提升編碼和列印的準確度與整體營運效率至關重要。對於追求準確RFID編碼與追蹤解決方案的產業領域,TSC Auto ID印表機穩定可靠,無疑是最佳選擇。

- 多元的產品線:提供桌上型與工業型RFID印表機,以滿足各式應用情境與標籤類型需求。T800 RFID桌上型印表機適用於不需頻繁列印的應用,如資產追蹤。針對庫存管理等大印量應用,T4000工業型RFID印表機則是不二選擇。

- 支援多種標籤:印表機支援標準與抗金屬標籤,靈活因應各種應用需求。

- 提升操作穩定性:更換或安裝新紙卷後,自動校準功能便會啟動,能減少標籤浪費、節省企業成本,尤其在使用較昂貴的抗金屬標籤時更具效益。

- 隨插即用:透過印表機語言模擬和TSC Auto ID的SDK (軟體開發工具包),可輕鬆對接現行在使用中的標籤模板及第三方平台 (如Inchz IoT的解決方案),簡化整合流程。

關於Inchz-IoT

Inchz-IoT是一家總部位於馬來西亞的雲端軟體解決方案供應商,提供全天候遠端支援,業務版圖遍及全球。其商業模式結合全球擴展能力、在地化服務與彈性的硬體整合方案,能夠有效滿足不同客戶的需求。Inchz-IoT提供橫跨RFID、行動裝置、自動識別、物聯網和工業4.0技術的全方位解決方案,透過軟體支援,實現應用效益最佳化與環境導向的系統化設定。