RFID Modernizes Inventory Management, Enabling Market Expansion

Background

Variety store chains focus on a wide range of products, making inventory management operations more complex. This complexity became an issue for a major Chinese variety store chain looking to expand into North America. In the past, they relied on barcode-based inventory management, which is generally a more labor-intensive method for tracking merchandise as each product label is scanned individually. Due to competitive labor costs, this was workable for them in China. However, upon expansion into North America, this process was unsustainable, especially in the U.S., where wages were up to 40% higher. To tackle this problem, the retailer turned to RFID technology and TSC Auto ID industrial RFID printers. Utilization of RFID enables bulk scanning to improve operational efficiency and reduce labor costs.

Challenges

After evaluation, the retailer decided to implement RFID tagging at their warehouses in China before shipping to North America. They sought an RFID printer provider that could effectively address three key challenges.

Scalable Capacity for Peak Periods

The retailer required robust printers for demanding warehouse settings to support its dynamic logistics operations, especially scalable capacity to handle volume surges during peak times. During these periods, up to 300,000 labels would be needed per day.

Multi-Label Usage Efficiency

As a variety store chain, the retailer sells products of varying sizes, from stationery to home furnishings. They needed printers that could easily accommodate up to 3 different RFID label types. Crucially, they needed the agility to switch between RFID label types effortlessly, avoiding constant recalibration that would result in downtime.

Optimal RFID Label & Printer Compatibility

The combination of the retailer’s single-write labels and legacy WMS’s printing architecture created challenges with RFID encodings, including duplicate- and cross-encodings and misprints. Additionally, the use of single-write RFID labels, which lack flexibility, led to encoding reliability issues.

Solutions

TSC Auto ID swiftly responded to the retailer within a week with practical solutions. By working closely with the retailer’s systems integrator, TSC Auto ID ensured that the hardware and software components aligned with existing workflows—setting the foundation for high-throughput, accurate RFID label production.

Encode During Print Functionality

With Encode During Print functionality, the T66R4e RFID printer could seamlessly meet high-volume label production requirements. With this capability, printing and RFID encoding are combined into one step, eliminating back-feed and maximizing throughput. Therefore, only 14 T66R4e printers were needed to meet the required peak capacity of 300,000 labels per day.

Quick-Access Label Configurations

The TSC Auto ID T66R4e RFID printer can store up to 8 label configurations for quick access by the operator. This capability significantly reduces downtime thanks to eliminating the time-consuming process of recalibrating the printer each time a new label type is loaded.

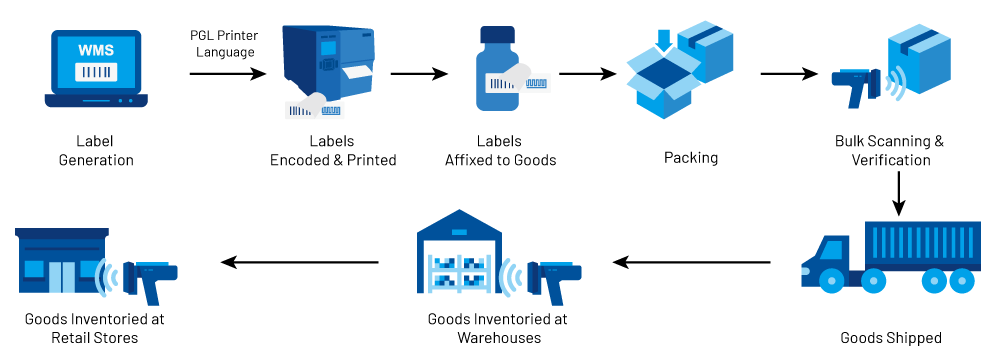

Transition to Direct Command-Based Printing

In conjunction with the systems integrator, the retailer’s WMS was adapted to support direct command-based printing with TSC Auto ID’s PGL printer language. This allowed it to generate and send print jobs to RFID printers directly without conversion via drivers. This offered several advantages, notably ensuring seamless compatibility between the single-write RFID labels and TSC Auto RFID printers, leading to more dependable encoding and complete utilization of the Encode During Print functionality.

Why TSC Auto ID

TSC Auto ID offers compelling solutions by combining its time-tested RFID printers and technologies with its established technical expertise and collaborative working method.

Proven RFID Printers & Technologies

With established RFID technologies, such as RFID printers, Encode During Print, and its proprietary PGL printer command language, TSC Auto ID is well-positioned to resolve customers’ unique needs, whether they involve printing capacity, system compatibility, encoding reliability, or beyond.

Technical Expertise & Collaborative Approach

TSC Auto ID is a trusted partner with the proven ability to quickly resolve complex challenges in close cooperation with customers and other vendors. With its longstanding technical expertise in auto-ID technology, including RFID, TSC Auto ID was able to effectively address issues like encoding inconsistencies (e.g., duplicate EPCs, missing data), batch reprints, suboptimal encoding speed, and deficient print command architecture. Their technicians resolved these issues within one week, outperforming competitors and securing the project.

Figure1: Role of TSC Auto ID RFID printers & PGL printer language.