Enabling Hospital EMR Adoption: One Barcode Printer Model, Many Departments

Background

When a new public hospital in Malaysia was preparing to be commissioned, it chose to adopt an Electronic Medical Record (EMR) system to enhance patient safety and streamline workflows. As a vital component of this initiative, they sought a single barcode printer model that could be seamlessly integrated across different workflows and departments.

Challenges

As a public institution, the hospital wanted a partner who understood the importance of balancing its technological goals with sustainable, long-term value.

The primary requirement was seamless printer adoption across multiple departments. For reduced operational complexity, they were interested in procuring just one printer model. Yet, the single model had to be capable of handling the different label needs of multiple departments (See Table 1). Within hospitals, labels can vary drastically in terms of size and materials. For example, inpatient departments commonly use patient identification wristbands, which are long-and-narrow and made from softer materials for comfort. Meanwhile, laboratory departments might utilize chemical- and temperature-resistant labels with conventional aspect-ratios for specimen vials.

In addition, the hospital prioritized long-term scalability to accommodate future growth. They required a solution that could evolve alongside their workflows, allowing them to implement new functionalities and process enhancements without the need for additional printer procurement.

Solutions

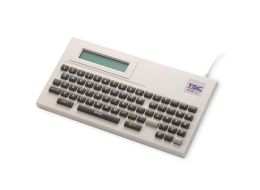

TSC Auto ID met the hospital’s challenges with the TH240 Series desktop printer, supported by the TSC Console Web printer management tool.

Table 1: Label Types & Dimensions Required per Hospital Department

| Department | Label Type(s) | Dimensions |

|---|---|---|

| Laboratory | Lab Label | 50mm W X 23 mm H |

| Outpatient | Patient/Diet/Radiology Labels | 73mm W X 23 mm H |

| Inpatient | Patient Identification Wristband | 90mm W X 50 mm H |

| Pharmacy | Prescription Label | 28mm W x 291mm H |

| Materials Management | Inventory Label | 35mm W X 30mm H |

The TH240 is designed to offer wide media support and was therefore an ideal solution. It can accommodate diverse media types and widths, including chemical- and temperature-resistant synthetic lab labels, tamper-proof paper or synthetic pharmacy labels, and durable PVC or Tyvek patient wristbands, among others (Table 1). The printer also features an easy-media-loading design and label-stabilizing media damper to ensure effortless media loading and print quality, respectively, for different media. For high-volume printing, a rear feed slot allows for external loading from a stack of fanfold labels or a large roll. Meanwhile, the modular architecture met the hospital’s desire for long-term scalability, allowing adaptation to new requirements via upgrade modules—such as a Bluetooth or Guillotine Cutter.

Image: TH240’s Easy-Media-Loading Design

The TH240 was proven in practice during an on-site Proof of Concept (PoC) where nurses and clinicians tested the printers in real-world scenarios to ensure they perform reliably. The TH240’s physical Reprint button was especially appreciated by staff for allowing them to duplicate labels instantly, removing time-consuming user interface interaction.

With the deployment of just one printer model and the implementation of TSC Console Web, the hospital’s maintenance effort was significantly reduced. TSC Console Web provided the IT team with a unified dashboard to monitor the health, status, configuration, and update of their entire TH240 printer fleet across all departments simultaneously, and in real-time. In addition, competitive warranty periods for both printers and thermal printheads helped to ensure reliable support during deployment and before the implementation of a long-term maintenance strategy.

Why TSC AUTO ID

TSC Auto ID helps customers balance long-term operational value with technical capabilities, leveraging a synergy of practical, user-centric design and software.

TSC Auto ID printers are designed to address the real-world pain points of users and operators. For example, TH Series 4-inch printers are designed to meet wide-ranging printing needs by accommodating diverse media types and widths. Also, modular upgradability allows the addition of new capabilities without new printer procurement, and features such as the easy-media-loading design and Reprint button are designed to enhance operational efficiency and usability. With value-added software, such as TSC Console Web, TSC Auto ID offers flexibility across operations, providing a variety of intuitive functions that integrate into existing environments.