Remote Printer Management Reduces Disruption to Manufacturing Workflow

SOTI Connect Prevents 12.5% Daily Production Loss with Enhanced Management and Predictability

Background

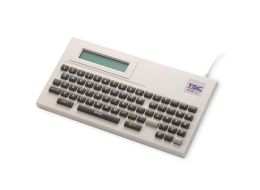

The Internet of Things continues to evolve in the industrial manufacturing environment. To keep up with ever-increasing customer demands, TSC Printronix Auto ID remains ahead by seeking digital transformation of its operation to improve factory performance in a high-volume production environment. It is common to see TSC Printronix Auto ID heavily leverage barcode labels to control and manage production on factory floors to streamline business processes.

Printer Downtime Causes Production Losses

As if assembling one printer with over a hundred pieces in the production line isn’t difficult enough already, TSC Printronix Auto ID’s factory is operating at full capacity, putting pressure on its staff to deliver these finished items on time. An unplanned one-hour outage will cut production by 12.5% per day!

Challenges

Managing Printer Fleets for Multi-Location Global Manufacturers

TSC Printronix Auto ID manufactures its products globally in Taiwan and China. The printer fleets are dispersed across many sites including print centers, packing facilities, FQC/OQC workstations, and more. Multiple printers are used in TSC Printronix Auto ID factories. This makes printer management challenging when managing, monitoring, and maintaining these printer fleets in terms of time, cost, and labor.

To avoid any production downtime, the maintenance team frequently works on-call shifts in the absence of a monitoring device for the printers’ operational conditions. The maintenance manager must re-prioritize scheduled assignments for urgent repairs due to unanticipated incidences, such as bad printhead dots. To find the source of the problem, a technician has to visit the printer’s physical location. Because replacement parts are required, the technician returns to the actual site to gather the supplies needed before they can resolve the breakdown issue. The issue isn’t just labor and time waste, it’s also unsustainable breakdown risks that result in massive losses.

Solution

The goal is to adopt modern technologies to control printers from a single interface at any time and any location. SOTI Connect is a flexible, expandable software for managing printers in an IoT network. The maintenance manager can use its intuitive dashboard to remotely set up, deploy, and manage printers, as well as review the data from printer conditions to manage the printers’ and essential parts’ lifespans.

One dashboard for better visibility: With SOTI Connect, the maintenance manager can see all printer statuses at any time, from any location. They can also alter the settings and optimize cross-branded printer performance, allowing the maintenance manager to set printer density and speed attributes at the same time to assure print quality with only a few clicks.

Gain real-time printer data for intelligent decisions: SOTI Connect collects valuable raw data 24 hours a day, seven days a week, allowing maintenance managers to monitor key parts and anticipate when they will wear out. By anticipating when to replace printheads and platen rollers, the maintenance manager can plan ahead for key parts replacement to maintain printer uptime. For instance, the maintenance manager can schedule automatic alerts before key parts wear out, such as the TPH odometer exceeding 23 km for thermal printheads and the platen roller over 45 km for printers.

SOTI Connect also enables managers to monitor all printer settings since the density and speed of all printers can change. With SOTI Connect, we can adjust them back to a specific setting

to ensure consistent quality of printed labels. By selecting the suitable density and/or speed, the maintenance manager can further analyze any abnormal settings and behaviors from operating printers to drive appropriate actions, thus maintaining high reliability of printer fleets.

Conclusion

SOTI Connect addresses key printer management challenges by streamlining the process. Remote assistance, preventive maintenance, and actionable data collection are all features that help to reduce production downtime and workflow disruptions.

| Feature | Value to users |

|---|---|

| Remote management from a single console |

|

| Preventive maintenance |

|

| Actionable data collection |

|